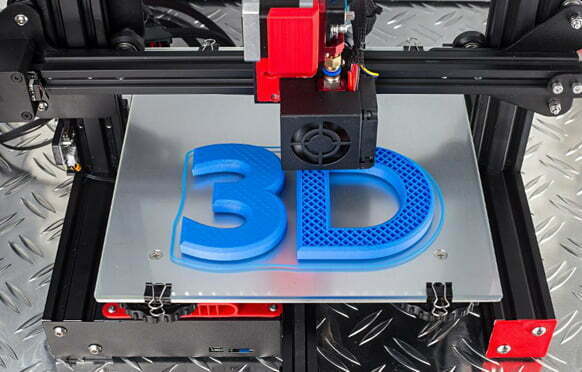

3D printing service in Dubai

How 3D printing will affect the Global Supply Chain?

What is 3D printing?

Five areas in which 3D printing has a huge effect on the supply chain and a cost edge

> Decentralizing manufacturing–

The technology’s “compact” nature would enable companies to move production quickly to the local markets or consumers. In consequence, we are going to see more local assembly centre shifts from mass manufacturing in low-cost countries. Companies would be able to manufacture components more closely than relying on imports. In periods of international uncertainty, for example during a trade war, this is particularly critical because the global cost of buying materials will grow rapidly.

> Customization of products–

3D printing service in Dubai, as a tool-less technique, allows producers unparalleled flexibility to customize their products on consumer needs. This would lead to more flexible production chains that can respond quickly to industry developments. Finally, design, development and delivery could fuse into a single supply chain function with larger customer participation in design and manufacture.

> Minimize complexity and increase time-to-market-

3D printing consolidates the number of production materials and processes. The effect on global supply chains, reduced complexity, saved cost for manufacturing, improved lead times and improved time to market would be important.

> Improving the use of resources–

3d printing Dubai is a greener manufacturing process that’s more energy-efficient and economical. It produces almost zero waste, eliminates the chance of surplus supply and stock and reduces the carbon footprint. It brings the production of ‘Just-in-Time’ to a new stage.

> Inventory and distribution rationalization–

The need to carry actual products across nations and regions will decrease when ‘on demand’ manufacturing becomes the norm. In combination with fewer SKUs for processing, this would have a significant effect on warehousing and logistics and the ability to cope with tariffs. Although the technology for 3D printing may sound like science fiction, science is currently the reality and it is now being felt. A very few applications in the real world have either been true or are right about the corner.

3D printing in tomorrow’s technology

> Aeronautics–

You will be surprised to hear that certain non-critical printed 3D pieces on aircraft are already used. GE currently has over 300 3D printers. By 2020, GE Aviation plans to manufacture 100,000 additional parts. Seventeen 3D printed pieces on the C5 Super Galaxy is mounted in the USA, which can save hundreds of millions.

> Building–

While it is still in its early stages, considerable progress has been achieved with the usage of 3D printers in the construction industries as the promise of the technology begins to be used by construction pioneers.